News

Hefei Sinopower Technologies Co., Ltd

Email:

Fax:

+86-551-63670623

WhatsApp:

China's first AEM electrolytic cell product was officially released

Release time:

2023-10-24

On February 16, the press conference of new products and integrated system of 2.5kW AEM electrolytic cell with the theme of "hydrogen production pioneer, zero carbon energy storage" was held in Shenzhen. Hydrogen energy electrolysis water hydrogen production equipment has the characteristics of low energy consumption, long service life, low water quality requirements, safety and reliability. DC power consumption of a single electrolytic cell is 4.3kWh/Nm ³, The working life of electrolytic cell is more than 30000h. With its excellent performance and economic advantages in hydrogen production, it will be used in large-scale molding of green hydrogen and other scenarios.

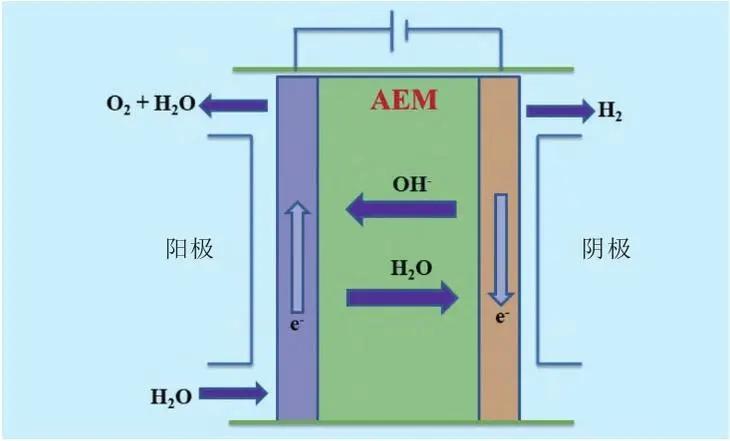

Electrolytic water hydrogen production technology can be roughly divided into four technical routes: alkaline electrolytic water hydrogen production (ALK), proton exchange membrane electrolytic water hydrogen production (PEM), solid oxide electrolytic water hydrogen production (SOEC), and anionic membrane electrolytic water hydrogen production (AEM). The technical characteristics and industrialization degree of these four technical routes are different, but also have their own advantages and disadvantages, and also have their own application space. AEM has advantages in catalyst, energy density, weight, volume, volatility, hydrogen purity and energy consumption.

In terms of the economy of hydrogen production, the rated power of a single electrolytic cell of stabilized hydrogen energy is 2.5kW, and the DC power consumption is 4.3kWh/Nm ³, The output pressure is 3MPa, the maximum hydrogen production is 600L/h, and the cold and hot start time is fast. The hot start time can reach 0-100% in 60 seconds, the cold start time is not more than 5 minutes, the working life of the electrolytic cell is more than 30000h, and the system life can reach 10 years.

As the third generation of electrolytic water hydrogen production technology, it also avoids the weaknesses of ALK products and PEM products, and has advantages in electrolytic cell price, system life, system operation and maintenance, and environmental protection.

In terms of flexibility, the new AEM electrolytic cell adopts the box-type installation mode suitable for the standard cabinet in the structural design, which can realize the system integration of different scales with multiple single equipment in parallel. At the same time, the software management of the integrated system can realize the data reading and recording of the electrolytic water hydrogen production equipment, equipment startup and shutdown control, operation status warning and alarm, equipment operation safety management and other functions. The control system is equipped with human-computer interface HMI, which reads the information of the electrolytic cell, and can monitor the operation of the equipment and realize remote control.

electrolytic